PHARMACEUTICAL

Measuring oxygen concentration in blister packs, patches, tubes, vials, and other modified atmosphere packaging. The device verifies oxygen levels to help maintain packaging integrity.

Oxygen concentration in blister packs – manual measurements

In the pharmaceutical industry, measuring of oxygen in packaging and monitoring its effect on product shelf life is critical.

For protection of oxygen sensitive pharmaceutics, pharmaceutical companies use nitrogen in the stage of packaging. With such method they prolong the lifetime of their products. The main problem is how to make reliable measurement in such small place without contamination of surrounding air in the sample of one blister pack. The sampling methods are not reliable because of high errors during sampling. The standard method using electrochemical sensor is not possible due to the fact that all electrochemical sensors consume some oxygen to operate, and this is a cause of non-stable signal and error in the measurement. The other problem is that classic probes are big, and it is very hard to make a measurement in small places in blister packs.

ECHO Instruments developed a special optical fibre oxygen measuring instrument, Hand O2, with custom designed software for measuring in blister packs. The optical fibre sensor makes a micro hole in the blister pack sealed with special silicon sealing patch. With such a small sensor we can measure in very small places and without any error caused by the surrounding air.

The instrument has IQ and OQ and the software is compiled for the pharmaceutical industry with automatic statistical evaluation and report output. Some of the biggest pharmaceutical companies use the Hand O2 in their daily quality control in blister packs production.

Oxygen concentration in blister packs – automatic system

B-O2 has been designed for automatic measurements of oxygen concentration in blister packs.

The device eliminates human error during measurements and, therefore, enables the highest accuracy and reproducibility of measurements in blister packs. It was specially designed as an assistance and control instrument for rapid routine checking of oxygen concentration in blister packs at the production site.

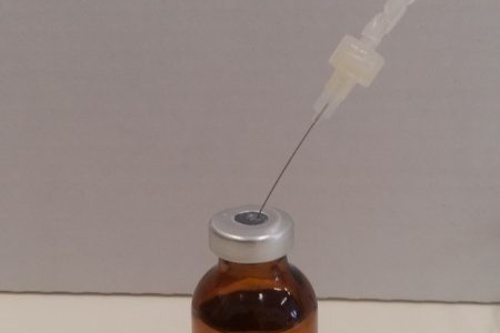

Oxygen concentration in vials

The measurements can be made in headspace as well as in the liquid part of the vial.

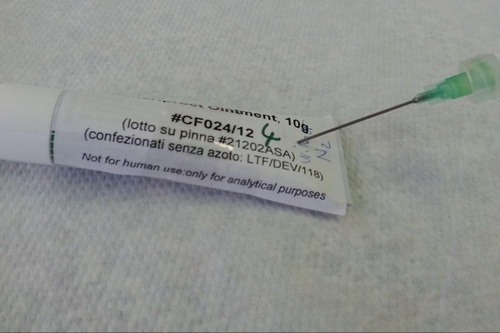

Oxygen concentration in tubes

The measurements are made in the part of the tube where the “air gap” is located.

Oxygen concentration in nicotine patches/wafers

The patches and wafers are flushed with nitrogen for prolonged product lifetime. There is still a small micro “air gap” in the product, which needs to be analysed to determine the efficiency of MAP packaging.